We recommend contacting the lower water authority!

DOSING RECOMMENDATION

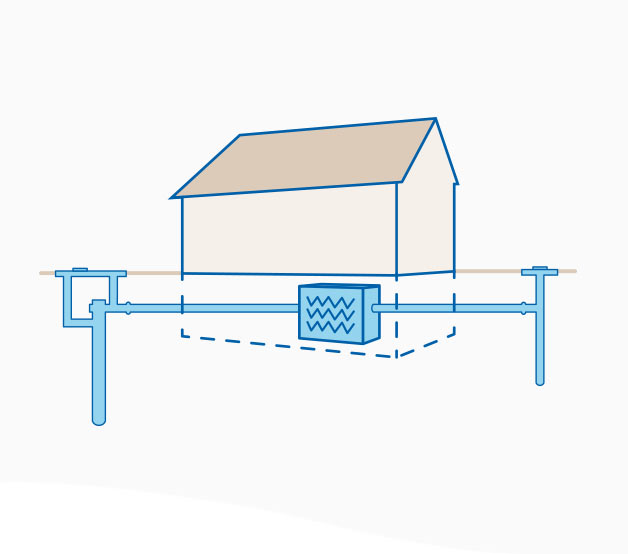

We recommend for heat pump cleaning:

3 x 400g bag WESSOCLEAN AQUA TYP 1

AVAILABLE AS:

FOR FURTHER INFORMATION AND QUESTIONS ABOUT ORDERING

CALL US:

+49 (0) 911-590601 20

Sorgen Sie für eine sichere Wasserversorgung

WESSOCLEAN AQUA TYP 1 entfernt mineralische Verkrustungen und biologische Verunreinigungen effektiv. Die ursprüngliche Leistung des Brunnens wird wiederhergestellt und die Wasserqualität sichergestellt.

SEHR EFFEKTIV, wirksam gegen:

1. Eisenoxide

2. Mangan-Oxide

3. Schleim

4. Biofilme

Innerhalb von 12 bis 14 Stunden werden die Blockaden im Brunnen, im Filterkies und in der Umgebungsgeologie gelöst.

EINFACH ZU VERWENDEN:

1. Brunnen öffnen (Deckel, Ventile)

2. WESSOCLEAN AQUA Typ 1 anmischen und in den Brunnen einführen

3. 12 bis14 Stunden (nicht länger als 24 Stunden!) einwirken lassen

4. Abschließend WESSOCLEAN AQUA Typ 1 aus dem Brunnen pumpen

Für eine Regenerierung mit WESSOCLEAN AQUA Typ 1 ist keine schwere Ausrüstung erforderlich. Brunneneinbauten wie Pumpen können während des Reinigungsvorgangs im Brunnen bleiben.